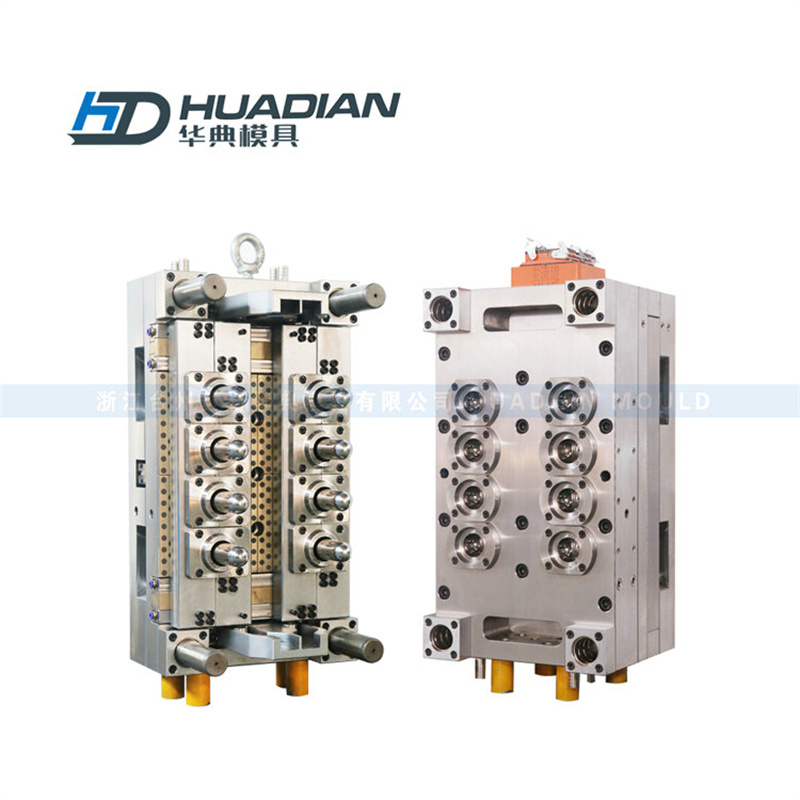

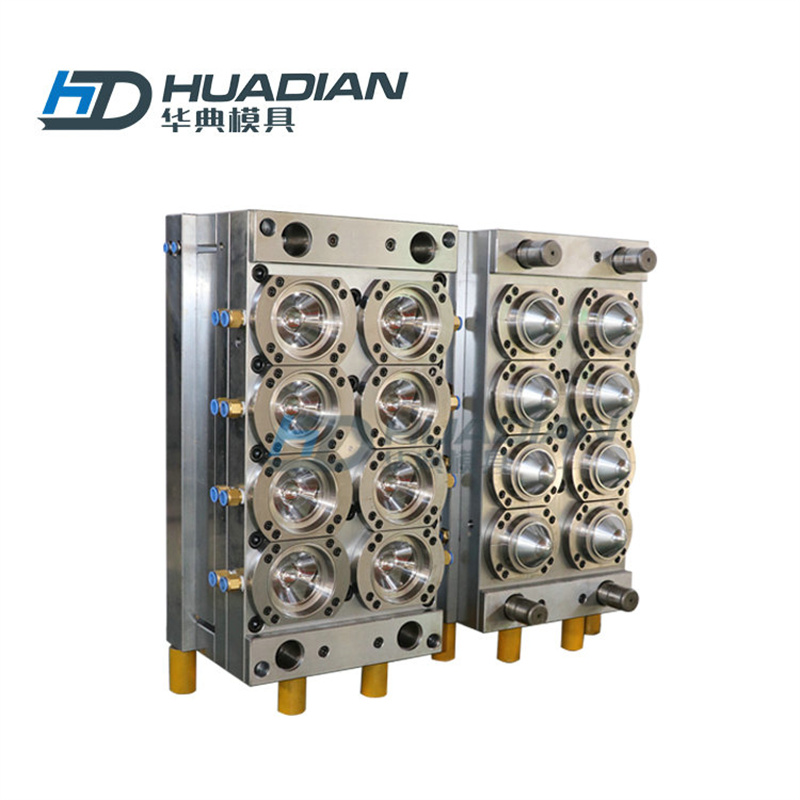

32 Cavities Suna Yi Mold

Ƙayyadaddun bayanai

| Kogo | Yi | Girman Mold | Mold Nauyin | Lokacin Zagayowar | |||

| Nauyi(g) | wuya (mm) | Tsayi (mm) | Nisa (mm)) | Kauri (mm) | (kg) | (dakika) | |

| 2 (1*2) | 720 | 55 | 470 | 300 | 608 | 330 | 125 |

| 4(2*2) | 720 | 55 | 490 | 480 | 730 | 440 | 130 |

| 8 (2*4) | 16 | 28 | 450 | 350 | 410 | 475 | 18 |

| 12 (2*6) | 16 | 28 | 600 | 350 | 415 | 625 | 18 |

| 16 (2*8) | 21 | 28 | 730 | 380 | 445 | 690 | 22 |

| 24 (3*8) | 28 | 28 | 770 | 460 | 457 | 1070 | 28 |

| 32 (4*8) | 36 | 28 | 810 | 590 | 515 | 1590 | 28 |

| 48(4*12) | 36 | 28 | 1070 | 590 | 535 | 2286 | 30 |

Fa'idar akan Fasahar Gudun Gudun Wuta

1. Rage almubazzaranci da tsadar kayan masarufi.

2. Rage aikin don sake yin fa'ida, rarrabuwa, fasa, bushe, da adana sharar gida, inganta ingantaccen aikin, adana lokaci da sarari.

3.Avoid don amfani da kayan da aka dawo da su wanda zai tasiri ingancin samfurin.

4.Guarantee samfurin a cikin matakin inganci iri ɗaya

5.Increase allura volum, Inganta da compressibiity na filastik narke

6.Intesify aikin allura, inganta fasaha

7.Rage lokacin allura da kiyayewa

8.Rage Ƙarfin Ƙarfi

9.Shorten Mold bude bugun jini na aikin allura, Kashe lokacin fitar da kayan Nozzle

10.Shorten da allura sake zagayowar, inganta aiki da kai da kuma aiki yadda ya dace

Mabuɗin Ayyukan Tsarin Runner Hot

1.Control zafin jiki na filastik narke daidai, Kashe lalata kayan.

2.Naturally daidaita mai gudu desgin, Mold Cavity a ko'ina cike.

3.Suitable size of Hot nozzle iya tabbatar da filastik narke mobile nasara da mold rami suna cike a ko'ina.

4.Correct tsarin kofa da girman zai iya ba da tabbacin kogin mold a ko'ina cike, Ƙofar bawul ɗin allura ta rufe cikin lokaci, don rage lokacin sake zagayowar.

5. Babu mataccen kusurwa a cikin mai gudu, inshora don canza launi da sauri, kauce wa lalata kayan.

6. Rage Matsi asarar

7. Lokacin kiyaye matsi yana da ma'ana.

HuaDian Mold - bayanan ƙira

| A'A. | Suna | Bayani | Tauri | |

| 1 | Mold tushe abu | P20 | 28-32 | |

| 2 | Core, kogo | S136 | 48-52 | |

| 3 | Murƙushe wuya | S136 | 48-52 | |

| 4 | Yanayin sanyaya | Mold core, wuyansa sanyaya | ||

| 5 | Yanayin sanyaya don farantin core da farantin rami | 1 in, 1 waje | ||

| 6 | Daga tsakiya(MM) | "+/-0.08MM | ||

| 7 | Lokacin allurar zagaye | 8-23 seconds | ||

| 8 | Lokacin bayarwa | Kwanaki 55 bayan an tabbatar da desgins | ||

HUADIAN's 32-cavity hand press kwalban Yi Mold wani babban ingancin PET hannun buga kwalban kwalban, wanda aka ƙera shi tare da tsarin mai gudu mai zafi da nagartaccen software na CAD da UG, kuma ya dace da samar da buƙatun fagage daban-daban kamar kayan kwalliya da kayan kwalliya. masu kashe kwayoyin cuta.

HUADIAN's 32-cavity kwalban hannu da aka danna Yi Mold yana amfani da kayan ƙira mai inganci na P20 don tabbatar da dorewa da ƙarfin ƙirar.Mandar, rami da dunƙule buɗaɗɗen ƙirar duk an yi su da kayan S136 don tabbatar da daidaiton samfur da rayuwa.

Bugu da ƙari, ƙirar ƙirar tana ɗaukar tsarin mai gudu mai zafi da CAD, UG da sauran ƙirar software, wanda zai iya fahimtar mafi kyawun cikawa da tsarin allura, da haɓaka haɓakar samarwa da ingancin samfur.Dukkan sassa na gyaggyarawa an yi su ne da kayayyaki daga sanannun masana'antun duniya, kamar murfin murfin zafi na DPONT a Amurka, HOSTET's band hita a Jamus, da nozzles na jan karfe a Italiya, da sauransu, don tabbatar da ingancin ƙirar.

Bugu da ƙari, ƙirar tana sanye take da cavities 32, kowannensu yana da girman 4 * 8, wanda ke inganta haɓakar samarwa sosai.Hakanan an sanye shi da injin sarrafa kansa don sauƙin amfani da goyan bayan ingantacciyar allura mai inganci.

A ƙarshe, HUADIAN's 32-cavity kwalban hannu da aka danna Perform Mold yana da nau'ikan aikace-aikace da yawa, gami da kayan shafawa da magungunan kashe kwayoyin cuta.Ta yin amfani da wannan ƙirar, masana'antun za su iya samar da samfurori da sauri da inganci, da kuma rage farashin samarwa.

Gabaɗaya, HUADIAN's 32-cavity hand-press bottle Perform Mold yana da inganci mai inganci, mai inganci, mai ƙarancin farashi PET kwalaben kwalban hannu.Samfurin yana amfani da fasaha mafi ci gaba, kayan aiki da software, waɗanda za su iya tabbatar da ingancin samfuran masana'anta da ingancin samarwa.Idan kai masana'anta ne na kayan kwalliya ko magungunan kashe kwayoyin cuta, ko buƙatar samar da samfuran PET, wannan ƙirar zaɓi ce mai makawa a gare ku.